In Malaysia’s fast-growing industrial landscape — from construction to manufacturing to logistics — workplace hazards are an everyday reality. Understanding these risks is the first step toward creating a safer, compliant, and more productive work environment.

Whether you’re a safety officer, operations manager, or business owner, this guide walks you through the most common hazards and how to control them — with professional support where it matters most.

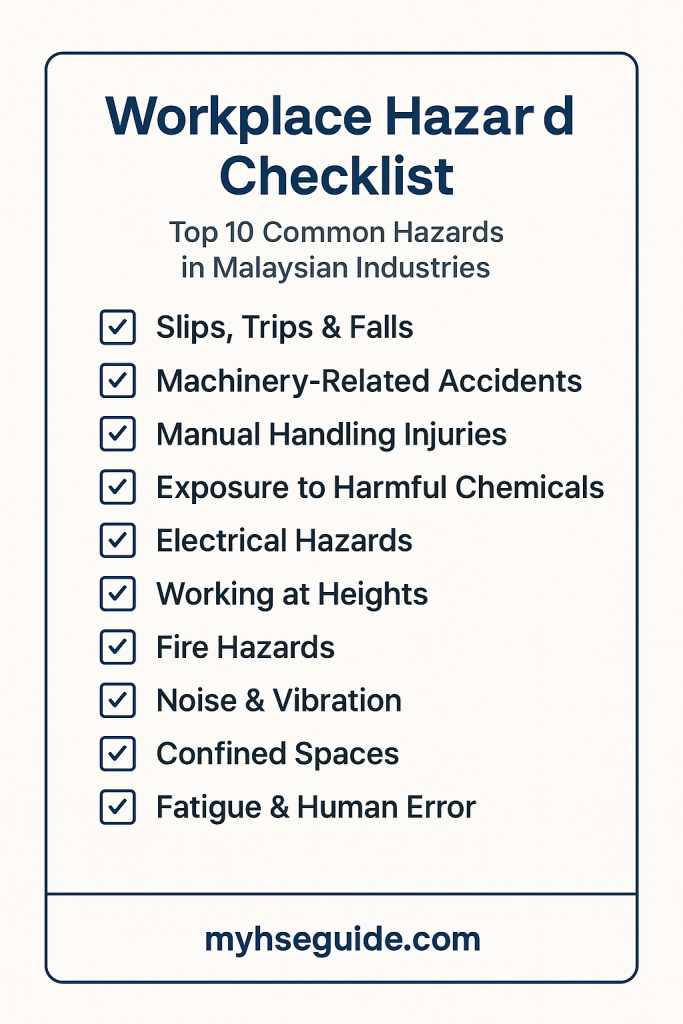

✅ 1. Slips, Trips & Falls

Hazard: Wet floors, uneven surfaces, cluttered walkways.

Impact: Minor injuries to serious fractures.

Control: Housekeeping SOPs, anti-slip flooring, warning signs.

✅ 2. Machinery-Related Accidents

Hazard: Unguarded moving parts, improper use, lack of training.

Impact: Cuts, amputations, fatalities.

Control: Guarding systems, Lockout-Tagout (LOTO) protocols, operator training.

✅ 3. Manual Handling Injuries

Hazard: Lifting heavy objects without aids or techniques.

Impact: Musculoskeletal injuries, chronic back pain.

Control: Ergonomics training, mechanical aids, task redesign.

✅ 4. Exposure to Harmful Chemicals

Hazard: Inhalation, skin contact, or ingestion of chemicals.

Impact: Respiratory issues, poisoning, long-term illness.

Control: Chemical safety training, SDS management, PPE, CIMAH compliance.

✅ 5. Electrical Hazards

Hazard: Exposed wiring, overloaded circuits, faulty equipment.

Impact: Electrical burns, shocks, fire.

Control: Regular inspections, isolation procedures, certified electricians.

✅ 6. Working at Heights

Hazard: Inadequate fall protection, improper scaffolding.

Impact: Fatal falls, severe injuries.

Control: Harness systems, edge protection, competent person training.

✅ 7. Fire Hazards

Hazard: Flammable materials, poor emergency preparedness.

Impact: Loss of property, life, and operations.

Control: Fire drills, extinguishers, ERT training, emergency response planning.

✅ 8. Noise & Vibration

Hazard: High-decibel machinery, continuous vibration exposure.

Impact: Hearing loss, hand-arm vibration syndrome.

Control: Audiometric testing, noise monitoring, PPE.

✅ 9. Confined Spaces

Hazard: Toxic gases, lack of oxygen, restricted exits.

Impact: Asphyxiation, fatal accidents.

Control: Confined space permits, atmospheric testing, rescue procedures.

✅ 10. Fatigue & Human Error

Hazard: Long shifts, high-stress environments, low awareness.

Impact: Mistakes, near-misses, poor decision-making.

Control: Job rotation, workload review, mental health support.

🛠️ Need Help Managing These Hazards?

Identifying hazards is just the start. The real challenge lies in implementing systematic, compliant, and effective control measures — that’s where PLC Group comes in.

💼 How PLC Group Can Help:

- ✅ Custom Safety Audits & Risk Assessments

- ✅ Emergency Response Training & Planning

- ✅ CIMAH & Chemical Safety Compliance

- ✅ HSE SOP & Documentation Development

- ✅ Safety Culture & Awareness Programs

📩 Ready to Make Your Workplace Safer?

Let our team of HSE experts support you in building a safer, more compliant business.

👉 Request a Free Consultation

👉 Or email us directly at: plc@plc-group.com

Stay safe. Stay compliant. Let’s make HSE a business advantage — together.

— The PLC Group Team